Going Through The Motions

The evolution of the robotic arm, a product invented in the U.S. that came to define modern factories around the world. It wasn't an easy sell in America.

Sponsored By … You?

If you find weird or unusual topics like this super-fascinating, the best way to tell us is to give us a nod on Ko-Fi. It helps ensure that we can keep this machine moving, support outside writers, and bring on the tools to support our writing. (Also it’s heartening when someone chips in.)

We accept advertising, too! Check out this page to learn more.

“So far, our application of universal transfer devices has been rather smooth. It does present a training requirement, the need for new skills because there will be a great force of technical specialists to operate and maintain the machines. We’ve moved slowly in this area.”

— Paul F. Guy, Ford Motor Company’s director of manufacturing, engineering, and systems, discussing the application of robotics into its business. Not that you’d know it from this 1980 quote in an interview with United Press International. See, Ford had the idea in the late 1970s and early 1980s to play down the fears of robotics entering the workforce by avoiding the phrase entirely, using instead the double-speakian term “universal transfer devices.” By the time Guy was using the term, the world had coalesced around calling automations industrial machines “robots.” But while cryptic, variations of the phrase could be found in the original patent for the robotic arm.

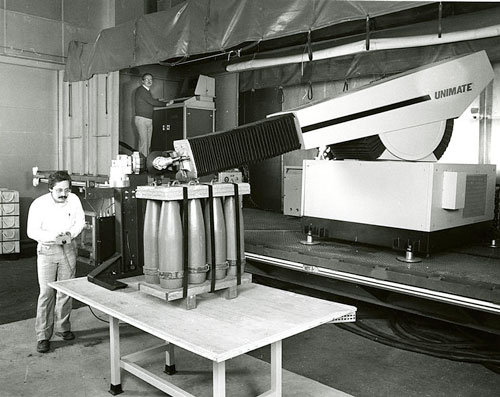

A Unimate device, used the Automated Manufacturing Research Facility at the National Institute of Standards and Technology (NIST Digital Collections/Wikimedia Commons)

The growth and evolution of the robotic arm

Like the growth of Apple two decades later, the birth of the industrial robotics needed two men to succeed.

And both were, at first, hesitant to call the thing a robot.

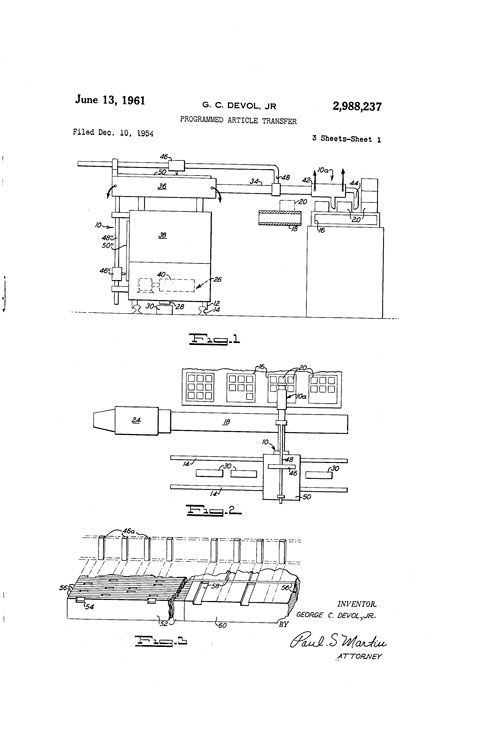

George Devol was the man who invented the robotic arm and whose name is on the patent that was filed for in 1954 and granted in 1961. But it was Joseph Engelberger, the man who cofounded the company Unimation, who sold that invention, the Unimate, to the industrial world.

The patent Devol came up with, under the unsuspecting name “programmed article transfer,” was effectively the first robotic arm.

This passage in its patent filing, which does not use the word “robot” once but does use variations on the term “universal transfer devices,” makes clear that the device was a robotic arm that would soon change the world—though the language, admittedly, is a bit on the dry side of things.

“The present invention makes available for the first time a more or less general purpose machine that has universal application to a vast diversity of applications where cyclic control is to be desired; and in this aspect, the invention accomplishes many important results,” the patent filing states.

Devol, a self-taught engineer, already had a long career in automation by the time he had met Engelberger in 1957. He had already applied for his robotic arm patent by the time the two had met, and his first company, United Cinephone, was the first firm to apply photocells to machinery, though as the company’s name suggests, the company actually started out in the film industry, with the goal of producing recording equipment for “talkies.”

Devol’s film technology was quickly beat in the market by giants like RCA, but he had cleverly realized that the photocells he had intended to use could also come in handy in other places—particularly the automatic door, a device Devol also invented.

In the 1940s, per Robotics Age, this automation led Devol to the idea of a “teachable machine,” a device that would function based on a list of commands saved magnetically into the machine. The success of that early patent eventually led Devol to come up with the idea of the robotic arm, or as he called it, a “manipulator.”

“After we had our teachable machine, we thought: why not make a manipulator? Let’s put a hand on the machine and move parts around,” Devol explained to the magazine.

At the time Engelberger and Devol first met at a cocktail party, bonding over science fiction, Engelberger was working at the aircraft division of the railroad equipment company Manning, Maxwell, and Moore, and quickly saw the potential in Devol’s idea. Soon, an opportunity to further follow through on the idea appeared after the railroad firm was sold off to a company that had no interest in aviation.

Working with another firm called Consolidated Diesel Electronic to help financially support the industrial robotics work, Engelberger worked toward building the business to support Devol’s invention. Soon after, Unimation—and its primary product, the Unimate—was born.

Devol wasn’t involved in the day-to-day business of Unimation and was in fact never even an employee of the company. He mostly focused on his own patent and invention business, so it was left to Engelberger to sell the concept to the world.

It created a odd situation for the history books: Devol was clearly the inventor of the robotic arm, but Engelberger became the “father of the robot.”

1968

The year that Marvin Minsky, the cofounder of the Massachusetts Institute of Technology's AI laboratory, came up with his “tentacle arm,” a robotic device that featured a number of joints, giving it a high level of flexibility. As shown in this video of the device in action, the added flexibility makes the arm strong enough to lift a person off the ground.

Five ways that the Unimate was first described in the media

- A British Movietone report described the Unimate as a machine that can “perform a multitude of tasks in a factory or laboratory as skillfully as a man, but without getting tired.”

- A 1961 New Scientist article described the device matter-of-factly, focused less on trying to oversell the device and more on telling readers what’s possible. “The hand is pneumatically operated and hence the gripping pressure can be controlled by adjusting the air pressure,” the article states. “Although the maximum gripping force at the end of 4-inch fingers is 180 lb., fragile objects can also be handled without difficulty.”

- A 1968 film in the British Pathé archive, meanwhile, described the device as “a robot that has more than a cool grip on things; it has a kind of mind which can be programmed like a computer.”

- A 1969 New York Times piece discussing a Unimate at a Ford plant that was nicknamed Clyde made a point of dwelling on the limits of the device. “Sightless, unable to perceive his environment and take action based on what he learns, Clyde is hardly in the league of the robots, cyborgs, and androids of science fiction,” Times science reporter William K. Stevens wrote in an article titled “Machine-Like Men Are Still Toddlers.”

- Popular Science, meanwhile, pondered the more esoteric use cases for the device in its 1962 article on the device. “If you want it to, this versatile automation will play ‘My Country ’Tis of Thee’ on a piano or xylophone,” author Alden P. Armagnac wrote. “It will pour coffee, into cups set at random on a table—as it’s pictured doing below. Or it will pick up alphabet blocks and spell its own name: ‘Unimate.’”

A display showing Unimates in action at the Toyota Commemorative Museum of Industry and Technology in Japan. (cotaro70s/Flickr)

The easy part of the first robotic arm was building it. Selling it was a bit harder.

When Devol developed the patent for what became the Unimate, it was not called a robot. And despite the term already being in the popular lexicon at the time thanks in no small part to the budding field of science fiction, it wasn’t clear whether the device should have been called a robot.

In part, this was because robots were still fairly novel concepts, and as a new company, they didn’t want to scare off potential customers who were looking for practical solutions, rather than devices from B-movies.

Engelberger, when meeting with the press, was initially careful not to oversell the technology. In a 1961 Bridgeport Post article discussing a press event hosted by Unimation soon after the company’s launch, he called the device a “manipulator” to emphasize it wasn’t sentient, and said that its abilities were an “extension of a human being.”

In his 1981 interview with Robotics Age, Devol ultimately made the case that since the public was calling it a robot anyway, Unimation probably should, too.

“You should have seen the time I had with Joe, getting him to call it a robot,” Devol recalled at the time. “He said, ‘Don’t do that. We’ll never get in the automobile industry or anyplace else.’”

Devol eventually sold Engelberger on using the term robot by pointing out that “no one knows what a manipulator is.”

Whatever the Unimate was, the $25,000 device did carry a lot of value in industrial settings, thanks to the fact that it could be programmed to have the industrial robot do the same thing thousands of times over hundreds of hours without the need of a break, a ton of repairs, or a vacation. The device could remember as many as 200 steps in a sequence, which is better than one can get away with on IFTTT.

Nomenclature debate or not, Unimation struggled for years to make headway. It sold its first prototype Unimate to General Motors in 1961, but it struggled to find other U.S. companies interested in its product. Ford, initially, demurred on aggressively using robotic arms in its own plants.

Part of the problem might have been the image problems that the robots created for their human workers. After GM built a highly automated plant in Lordstown, Ohio, in 1969, workers revolted because of a combination of layoffs and a much faster pace than they were used to. Per a 1972 Time piece, issues of “sabotage”—parts that were clearly left out of otherwise finished cars, or vehicles with clear signs of vandalism—became a problem at the plant.

GM partly created the problem because it added extra tasks to the workers’ jobs in an effort to ease the monotony of a job that likely would become mind-numbing otherwise, but Time reporter Edwin Reingold suggested that that wasn’t what employees actually wanted.

“Many workers complain that they do not want to work as hard as they are being asked to do,” Reingold stated. “It may well be that what were considered ordinary norms in the past are no longer acceptable.”

The company eventually found much more in the way of success outside of the U.S., where the labor concerns were less pronounced. Devol noted in his Robotics Age interview that Europe, driven by a Nokia-run factory in Finland, was a major area of success for the Unimation. (Fiat was a major customer of the company.)

Japan also became a successful market for the devices after the firm licensed out its technology to Kawasaki Heavy Industries in 1968. That move, as you might expect, played a big part in the rise of Japan as a major force in the auto industry in the 1980s—and also led to the Japanese robotics industry usurping the American one.

Eventually, U.S. companies bought in as well, and the robots redefined the auto industry in particular—even if, like Ford, they had to take great pains to soft-pedal the concept. The slow movement by corporate America, whatever the reason, cost the American robotics market its first-mover advantage.

“We’re handing it to the Japanese on a platter,” Devol noted in a 1983 Washington Post article. “I just can’t understand America.”

Unimation, despite inventing and popularizing the concept that redefined the industrial world, didn’t actually make a profit until 1975. The company was eventually crushed by its competitors, because of course it was.

1.2M

The number of units Nintendo sold of the Ultra Hand, a device released in 1966 that was the company’s first non-electronic toy. (It was effectively a giant clamp with two hands on the end—not electronic, but somewhat in the same spirit as the robotic arm.) The toy, created by famed Nintendo inventor Gunpei Yokoi, would inspire another, better-known device which he created roughly two decades later—the Family Computer Robot, or Robotic Operating Buddy (R.O.B.), a robotic-armed device that worked in tandem with the games Gyromite and Stack-Up. That device, while not a massive hit, played a key role in Nintendo’s success as it helped convince toy-sellers to stock the Nintendo Entertainment System after the video game crash of 1983.

The story of the creation of the industrial robotic arm ends in a somewhat strange place: the bowling alley.

Clearly, automation has made the experience of bowling much better than it could have been otherwise, with machinery clearing the pins, picking them up, and ensuring the ball gets back to the bowler when he or she needs it. Heck, modern machines can even keep score.

One of the largest bowling alley operators in the country, a company called AMF, has an unsuspecting name, but it stands for something surprisingly industrial: American Machine and Foundry. The company, which has roots dating back to 1900, spent time as a major defense-industry supplier to the U.S. government during the early years of the Cold War, acquiring the rights to the first automatic pin-setter around the same time.

During this period, AMF became the second company to develop an industrial robotic arm, and started developing a device called the Versatile Transfer Machine, or the Versatran, in 1958. The device, which doesn’t even have a Wikipedia page despite likely being just as important to the robot’s role in the industrial revolution, competed with Unimate on the market for years, and even had somewhat of a home-field advantage because the device was created in Michigan, not far from home of the U.S. auto industry.

The industrial robot business was eventually sold off to a firm named Prab, and AMF eventually put its focus on bowling and other recreational pastimes.

When George Devol died in 2011, he got the full New York Times obit treatment. After Versatran co-inventor Veljko Milenkovic died in 2009, his passing was mentioned on a LiveJournal page by his daughter—a great personal story, but an unfortunate oversight by the history books.

You’d never know AMF played such a key role in the creation of the industrial robot … until you consider the fact that, in a lot of ways, the bowling alley contains many of the elements of automation that the robotic arm does so well. Like the robotic arm, the bowling alley follows a script and is heavily automated. We think of it as a game—a sport, even—but when broken down, it’s a matter of humans interacting with a giant machine for recreational purposes.

In that light, it’s only natural that bowling and robotic arms have this strange connection.

:format(jpeg)/2018/04/tedium041918.gif)

/2018/04/tedium041918.gif)

/uploads/ernie_crop.jpg)