But in the early 1980s, a man named Walter Düring had such a moment. The Swiss man’s company, Düring AG, had made a name for itself with the concept of decalcification, based on a formula his mother, Maria, came up with. But it was in the early 1980s that the firm had come up with something truly successful on a mainstream stage: A uniquely shaped nozzle that could spray decalcifiers into obscure crevices.

That tool, known as Toilet Duck, or WC-Ente, was basically perfect for its task. Designed to hit spots of the toilet bowl not easily reachable through scrubbing or even spraying alone, the brand gained a lot of attention starting in the 1990s for its unusual design, which, like the plastic lemon, was a product that was all design.

“The appropriately named Toilet Duck broke ranks with the conventionally bottled toilet-cleaning products by proclaiming, through the pack shape alone, its ease of use for the intended purpose,” author Bill Stewart wrote in his 1995 book Packaging as an Effective Marketing Tool. “There was little doubt in the minds of shoppers that the pack would perform better than conventional containers.“

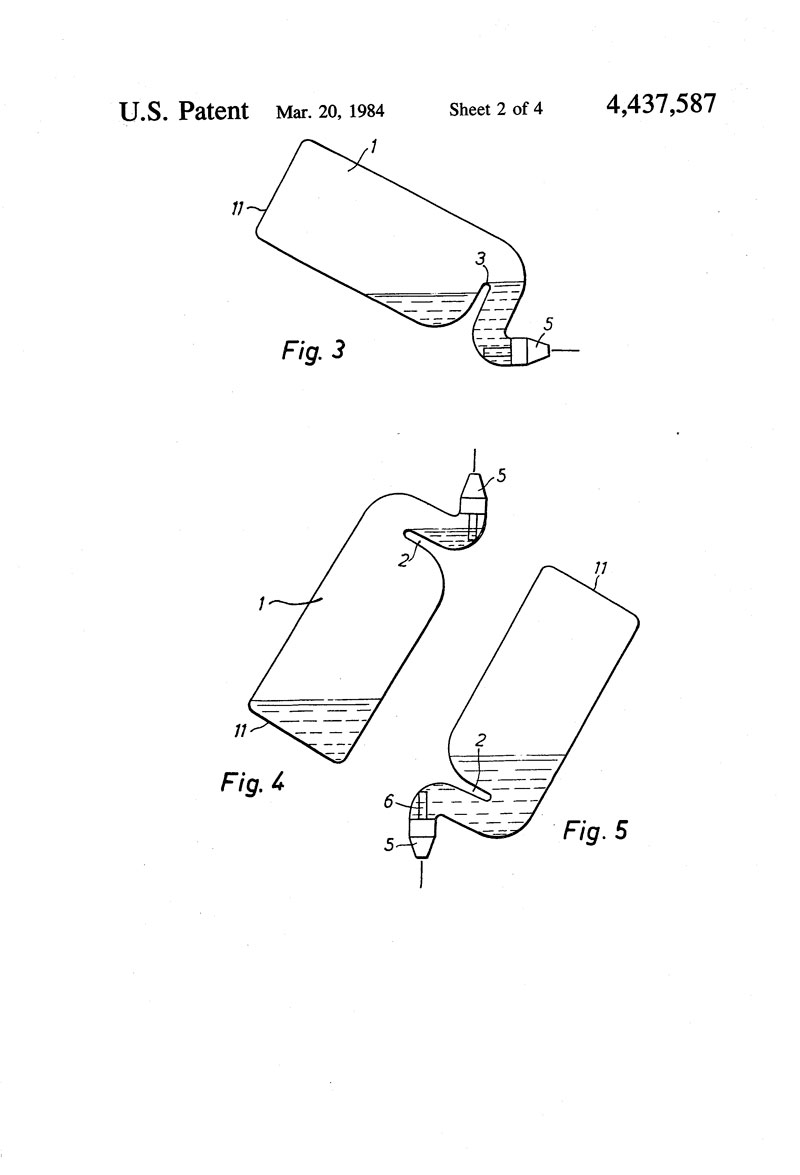

A Toilet Duck patent drawing.

But there was one major difference: The duck design, which is now owned by S.C. Johnson, was clearly something brand new, that hadn’t been invented before. As such, the container received a U.S. patent in 1984. The patent makes clear that the design required some thoughtful engineering work to do its job:

By means of this construction, it is possible to spray a liquid stream from the supply retained in the smaller chamber in any desired direction, independently of the volume remaining available in the larger chamber of the bottle as long as there is liquid in the smaller chamber. Since the bottle takes up only a small height in its horizontal position, the stream hits spots which are unaccessible to bottles held in an upright position. Furthermore, it is possible to produce the bottle in common bottle manufacturing machines once the blow mold has been adapted, whereby the greater difficulties and additional working steps caused by sharply angled nozzles are avoided.

Most people wouldn’t look at the toilet as a potential hotbed of innovation—we go out of our way to hide our use of ‘em, despite the fact that everyone knows that everyone uses them.

But the person who does see the innovation potential is the one who gets to file the patent, of course. Maybe we need to be willing to find a little more toilet inspiration—hey, you never know, you could come up with the next Toilet Duck.

:format(jpeg)/2017/07/0705_toiletduck2.jpg)

/2017/07/0705_toiletduck2.jpg)

/uploads/ernie_crop.jpg)